About Cotton Ginning Process

First Raw cotton is picked by farmer from farm & collect it and brought to Cotton Ginners by Transport for sale.

Cotton Ginner assort all farmer’s cotton & make separate heap of cotton according to quality of cotton steppe length, colour, etc. and start process.

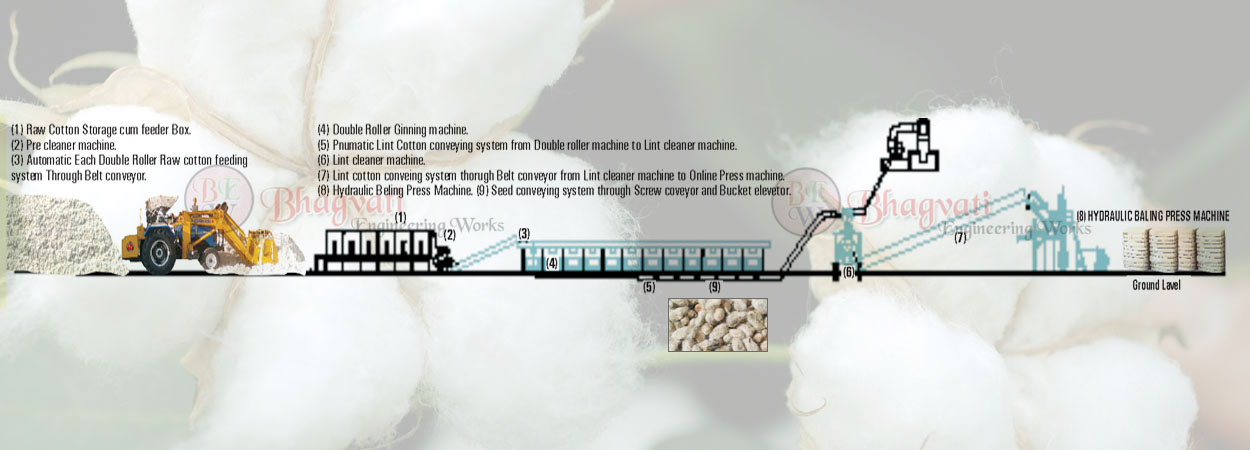

In Ginning plant first all as cotton feed into Unique feeding control system Box, Then this machine feed cotton in Pre-cleaner machine and plant uniform level.

High Tech Pre – cleaner machine clean raw cotton by removing impurity like leaf, Stick piece, sends, small stone, un opened cotton boll, dust, etc.

Then cotton is convey through Belt conveyor to feed into Double Roller gin machine.

Double roller Gin machine separate Lint cotton (Fiber) and Cotton seed.

Lint cotton ( fiber) is conveyed through Belt conveyor or Pneumatically to Lint cleaner machine.

Cotton seed is convey through screw conveyor and Bucket elevator to outside Gin House for oil mill process.

Lint cleaner machine Open cotton fiber & clean the fiber by removing impurity like small leaf piece, sends, short fiber, etc. And convey Lint cotton (fiber) Into belt conveyor.

Through Belt conveyor Lint cotton (fiber) is feed into Hydraulic Baling press machine Passing through Humidification system.

Humidification system is install in plant to apply humid air on Lint cotton (fiber) to make Lint cotton (fiber) soft for easy pressing process. There is two way to apply humid air in cotton . One is cold water generated humid air & second is hot water steam generated humid air.

Then Lint cotton(fiber) is pressed in Hydraulic baling press machine and we get Lint cotton (fiber) in Bale form with tieing pet strep or G.I. Wired. and pack it with warping cotton cloth or plastics bag. And make Print with detail of Manufacture name, Address,batch Code,weight,quality detail,process Date, etc.

Finish Product lint cotton (fiber) Bale is ready for sale at spinning mill. Bale size is 18 inch x 18 inch x 48 inch and weight is 165 to 180 kg.